About Us

We are an association of committed companies, scientific partners and interested parties who are developing solutions for the upcoming tasks of the circular economy of lithium-ion batteries and future technologies.

We are only at the beginning of a development in which large quantities of electrical storage systems are required for applications in mobility and energy supply. These are currently lithium-ion battery systems. New technologies such as solid-state batteries and other cell chemistries are currently under development.

Most of the battery materials come from raw material sources outside the EU. The long supply routes are resource-intensive and prone to failure. It is therefore our common goal to first use existing batteries for as long as possible, possibly in a second application, and then to recover the raw materials contained in the batteries using the most efficient recycling processes possible and use them for new production.

Through the interaction of the various value creation partners along the battery production – use – reuse – recycling process chain, we identify potential synergies that lead to a new level of efficiency in the entire material cycle with lower environmental impact.

Pragmatic approaches such as automation technology, logistics and fire protection are being pursued. In addition, digitalization with lifecycle-accompanying system solutions offers potential for recording and optimizing the overall process.

Current challenges in the value creation cycle

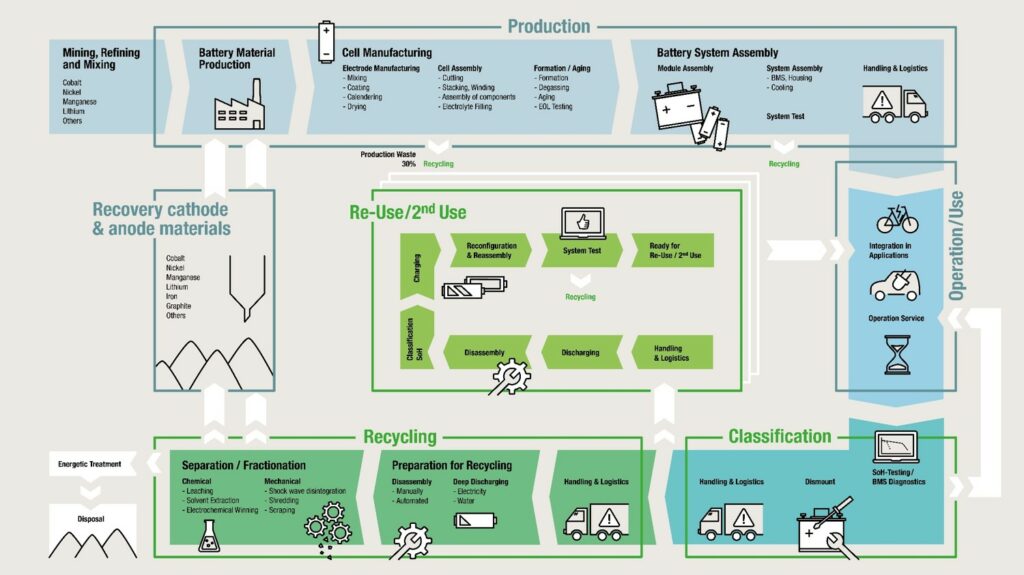

The battery value chain includes a large number of different processes and technologies that are constantly undergoing further development.

The first step is the production of battery materials, battery cells and complete systems. This requires various forms of highly qualified automation technology for battery cell production and battery system assembly. Throughout the entire value chain, important cross-sectional tasks include logistics, in particular transportation and safe storage, as well as fire protection, both in the manufacturing process and in storage.

For new developments, testing and classification form the basis for safe use and are a mandatory prerequisite for the reuse of used batteries. Recycling and reuse will play a central role in the availability and affordability of raw materials. New processes will help to reduce dependencies on raw materials and secure supply chains.

New battery technologies must be developed in line with technological progress. Various analytical and characterization skills are required for material development. Digital solutions for considering the entire life cycle (battery passport, life cycle assessment) must also be developed and implemented.

Our Services

Our Team - Battery Network ReLioS e.V.

Carl-Ernst Forchert

Chairman of the Board

i-vector Innovationsmanagement GmbH

Managing Director

Phone: +49 30 22 500 321

E-Mail: forchert@relios.org

Web: www.i-vector.de

Prof. Jung-Hwa Lee Ph.D.

Deputy Chairman of the Board

Berliner Hochschule für Technik (BHT), Automation Technology

Professor of Mechanical Engineering / Automation Technology

Phone: +49 30 45 045 185

E-Mail: lee@relios.org

Web: www. bht-berlin.de

Antje Roettcher

Board Member

Stöbich Brandschutz GmbH

Key Account Management International

Phone: +49 5321 5708 1964

E-Mail: roettcher@relios.org

Web: www.stoebich.com

Angela Blume

Network Manager

i-vector Innovationsmanagement GmbH

Project Manager

Phone: +49 30 22 500 323

E-Mail: blume@relios.org

Web: www.i-vector.de